Granite surfaces enhance aesthetics in kitchens and bathrooms.

Granite is widely used for kitchen countertops, bathroom vanities, and other surface areas where durability, resistance to heat and scratches, and aesthetic appeal are desired. Its natural beauty, availability in different colors and patterns, and durability make it a popular choice for high-end residential and commercial projects. Granite is utilized as flooring material in homes, offices, hotels, and public spaces. Its hardness, durability, and resistance to wear make it suitable for high-traffic areas. Granite tiles or slabs are also used as wall cladding, adding an elegant and timeless look to interior and exterior walls.

Granite is often used as a cladding material for building facades. It provides a durable and visually striking exterior finish, enhancing the aesthetics of the structure. Granite facades are known for their longevity, resistance to weathering, and low maintenance requirements. Granite has been used for centuries in the construction of monuments, memorials, and gravestones. Its durability, ability to withstand outdoor conditions, and its ability to retain its appearance over time make it a suitable material for creating lasting tributes.

The related granite and marble industries are one of the oldest industries in the world, dating back to the time of Egypt. There are ancient major exporters of modern granite include China, Iran, India, Italy, Brazil, Norway, Canada, Turkey, Spain and the United States. Granite is one of the stones that can be used both indoors and outdoors. Among its applications with uneven or polished surface, we can mention items such as stair treads, sidewalks, kitchen counters, floors, wall coverings, washbasins, kitchen sinks and landscaping. Granite is a rock from the heart of the earth and is known as the inner igneous that has large grains (minerals). Granite colors are usually pink, white, gray and black.

Internal igneous rock means that the molten rock inside the shell cools and never as molten rock. It does not go out of the shell. Gradual cooling of molten rock to form large crystals of a mineral that there are essentials in granites. Over time, the solidification of molten rock depends on its chemical composition available within the shell, it makes different types of minerals in different time periods form and change the final granite. Therefore, the grain size on granite fits how cooling is molten rock.

Granite is utilized in landscaping projects for pathways, patios, retaining walls, and other outdoor features. Its natural beauty, durability, and resistance to weathering make it a popular choice for creating functional and visually appealing outdoor spaces. Granite can be used in the construction of bridges, piers, and other infrastructure projects. Its strength, durability, and resistance to erosion make it suitable for withstanding heavy loads and harsh environmental conditions. Granite is often incorporated into interior design elements such as fireplace surrounds, staircases, columns, and decorative accents. Its natural beauty and variety of colors and patterns allow for unique and customized designs.

Granite can be used to create sinks, washbasins, and other bathroom fixtures. Its durability and resistance to stains and moisture make it a suitable material for these applications. Granite is occasionally used for tabletops, desks, and other furniture pieces. Its durability and resistance to scratches make it an attractive option for furniture that requires a sturdy and long-lasting surface. Due to its hardness and resistance to abrasion, granite is used in various industrial applications. It can be found in machinery bases, precision surfaces, laboratory countertops, and other industrial settings where strength and durability are crucial.

-

Granite, while known for its durability, has several disadvantages that can impact its use in construction and design. It is susceptible to cracks from extreme temperature changes or improper installation, necessitating careful handling and adherence to installation guidelines. The material"s design flexibility is limited compared to alternatives like engineered stone, making intricate designs challenging and potentially wasteful. Additionally, granite can be expensive due to extraction, transportation, and installation costs, which vary based on quality and rarity. Its heavy weight requires structural support during installation, complicating the process further. Unique varieties may be hard to source, affecting availability and pricing. Although granite"s natural variations in color are often seen as attractive, they can pose challenges for projects requiring uniformity. The stone is also porous and needs regular sealing to prevent staining from liquids.

Maintenance involves routine cleaning and periodic resealing to maintain its appearance. Professional installation is typically required due to granite"s weight and specific handling needs, adding to project costs. Finding large slabs without seams can be difficult, impacting aesthetic appeal. Furthermore, granite surfaces can feel cold and hard to the touch, which may not be comfortable for all users. Lastly, the environmental impact of granite extraction raises sustainability concerns; however, the industry is moving towards more responsible practices. "

-

West Asian granites, sourced from countries like Saudi Arabia, Iran, Turkey, and Egypt, showcase a diverse range of colors and patterns due to the region"s geological diversity. Common hues include beige, brown, gray, and pink, offering numerous design possibilities for architectural applications. The abundance of granite resources in the Middle East eliminates the need for imports and provides a cost-effective option for builders. Known for their durability and longevity, these granites resist wear, weathering, and chemical exposure. They are suitable for various uses including flooring, countertops, and decorative elements in both residential and commercial spaces. Additionally, West Asian granites are compatible with materials like steel and wood, enhancing their versatility in design. Their heat resistance makes them ideal for kitchen surfaces while their non-porous nature ensures high resistance to water penetration. The cultural significance of these granites is evident as they are often used in historical monuments and important structures throughout the region.

With an increasing focus on sustainability, quarrying practices are evolving to minimize environmental impacts while promoting responsible resource management. "

-

Granite is a versatile material widely used in both residential and commercial applications due to its durability, aesthetic appeal, and resistance to heat and scratches. Commonly found in kitchen countertops and bathroom vanities, granite also serves as flooring in high-traffic areas, wall cladding for interiors and exteriors, and facades for buildings. Its longevity makes it suitable for monuments and gravestones. The granite industry has ancient roots, with major exporters including China, India, Brazil, and Italy. The stone"s unique properties stem from its formation process, where molten rock cools slowly to create large mineral grains. Granite"s applications extend to landscaping features like pathways and patios, as well as infrastructure projects such as bridges due to its strength. Additionally, it is used in interior design elements like fireplace surrounds and furniture pieces due to its variety of colors and patterns. Industrial uses include machinery bases and laboratory countertops where durability is essential.

-

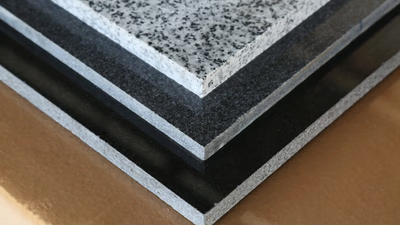

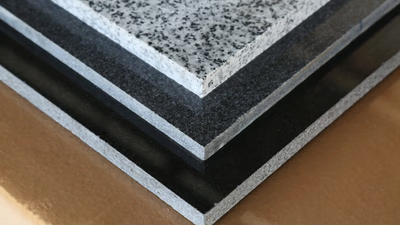

Granite is an igneous rock primarily composed of quartz, feldspar, and mica. Formed from the slow cooling of magma beneath the Earth"s surface, granite exhibits a coarse-grained texture with visible minerals that contribute to its speckled appearance. Its hardness and durability make it a favored building material for various applications, including countertops, flooring, wall cladding, and monuments. Granite"s aesthetic appeal is enhanced by its range of colors such as pink, gray, and black. It is also utilized structurally in foundations and retaining walls due to its strength. The stone"s resistance to scratches and weathering further solidifies its popularity in both residential and commercial construction projects. Granite is quarried globally, cut into slabs or tiles, polished for use in design projects, and serves as a crucial component in infrastructure like road construction. Crushed granite is often used as an aggregate in asphalt and concrete production due to its stability and wear resistance. "