Phosphoric acid"s role in agriculture and industry is significant. "

Phosphorus, the element from which phosphoric acid is derived, was first discovered in the late 17th century by German alchemist Hennig Brand. He isolated phosphorus from human urine. However, it took several more decades for scientists to understand the true nature of phosphorus and its compounds. In the early 19th century, Swedish chemist Jöns Jacob Berzelius made significant contributions to the understanding of phosphoric acid. He conducted experiments on the reactions of phosphorus with various substances and described the formation of phosphoric acid.

The commercial production of phosphoric acid began in the mid-19th century. Initially, it was obtained by treating bones with sulfuric acid, leading to the term "bone acid." This process, known as the bone-ash process, involved the extraction of phosphate from bones to form calcium phosphate, which was then reacted with sulfuric acid to produce phosphoric acid. In the early 20th century, the wet process for phosphoric acid production was developed. This process involved the treatment of phosphate rock with sulfuric acid, resulting in the formation of phosphoric acid and calcium sulfate. The wet process gradually replaced the bone-ash process due to its efficiency and cost-effectiveness.

It is not clear exactly who made phosphoric acid for the first time and when, but historical records date the first invention of phosphorus to German alchemical work. Evidence suggests that Hennig Brand (t), an alchemist and merchant of the seventeenth and early eighteenth centuries (1730-1730) in Hamburg, Germany, discovered phosphorus in 1669 and, like other alchemists of the time, A brand looking for alchemy, kept his discovery a secret (like the alchemists before him), he tried to make gold using phosphorus (which he certainly did not succeed in). He used a liter of urine to produce about 120 grams of phosphorus!

Thus, the official production and discovery of phosphoric acid was delayed until the 1770s, according to official sources. Until two Swedish chemists, Johann Gottlibgan and Carl Wilhelm Schill, were completely independent of the brand notes, and succeeded in producing phosphoric acid from bone ash. Shale succeeded in separating phosphorus from bone ash in 1774, and in 1777, by adding nitric acid to phosphorus, he produced phosphoric acid. However, some sources have confirmed that the initial production of phosphoric acid have been in 1694 by Robert Boyle with the dissolution of phosphorus pentoxide in water.

The development of phosphoric acid played a significant role in agricultural practices. Prior to the discovery and understanding of phosphoric acid, farmers relied on natural sources of phosphorus, such as animal manure and bone meal, to enrich their soils. The availability of phosphoric acid as a concentrated form of phosphorus allowed for more efficient and targeted fertilizer application, leading to increased crop yields. In the early stages of phosphoric acid's discovery, scientists had limited knowledge of its chemical structure and properties. It was not until the late 19th century that the molecular structure of phosphoric acid (H₃PO₄) was fully elucidated. This understanding helped pave the way for further research and applications of phosphoric acid in various industries.

In the mid-20th century, the thermal process for phosphoric acid production gained prominence. This process involved burning elemental phosphorus in an excess of air to produce phosphorus pentoxide (P₂O₅). The resulting phosphorus pentoxide was dissolved in water to form phosphoric acid. Today, both the wet process and the thermal process are widely used for the industrial production of phosphoric acid. The choice of process depends on factors such as the quality of the phosphate rock, energy availability, and environmental considerations.

The industrial applications of phosphoric acid expanded over time. In addition to its use as a fertilizer, phosphoric acid found its way into diverse sectors. For example, in the early 20th century, phosphoric acid began to be used in the production of detergents and soaps. Its acidic properties made it effective in removing mineral deposits and stains from fabrics and surfaces. Phosphoric acid's association with the food and beverage industry emerged in the mid-20th century. It was recognized as an acidulant, providing a tart flavor and enhancing the taste of various products. The introduction of carbonated soft drinks, such as colas, led to phosphoric acid's widespread use as a flavoring and pH adjuster in these beverages. Its addition helped balance the sweetness and provided a characteristic tangy taste.

As the use of phosphoric acid in food and beverages increased, regulatory bodies became involved in setting guidelines and safety standards. Authorities such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have established maximum allowed levels of phosphoric acid in different food products to ensure consumer safety and prevent excessive intake. In recent years, there has been growing awareness of the environmental impact associated with phosphoric acid production and its use in fertilizers. The mining and processing of phosphate rock, the primary raw material for phosphoric acid, can have adverse effects on ecosystems and water quality. Efforts are being made to improve the efficiency of phosphate mining and reduce environmental pollution.

-

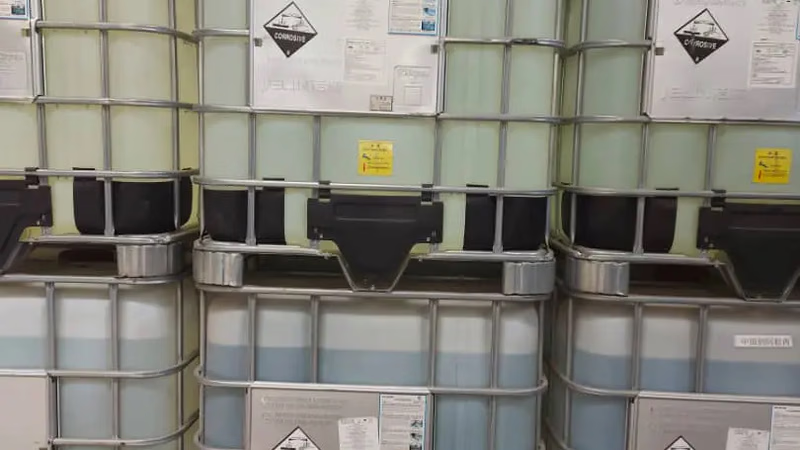

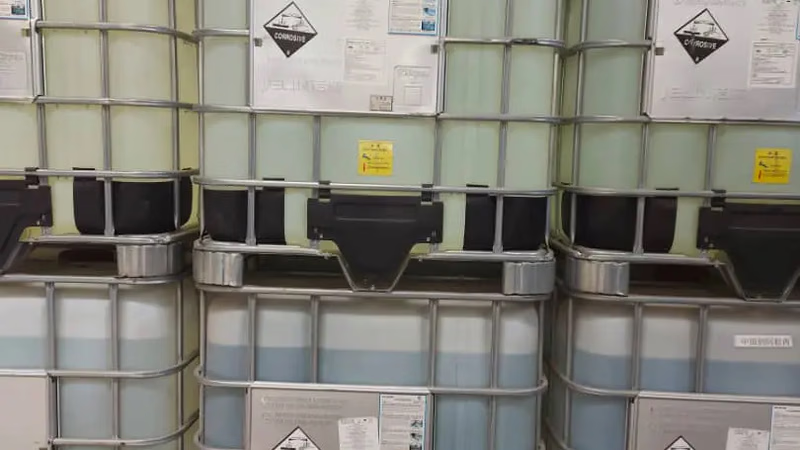

Phosphoric acid, or orthophosphoric acid, is a mineral acid with the formula H₃PO₄. It is produced through either the wet or thermal process. The wet process involves reacting phosphate rock with sulfuric acid, resulting in a mixture that is filtered and purified to yield phosphoric acid. This triprotic acid has a pH of around 2. 2, indicating its strong acidity. Phosphoric acid is widely used in various industries, particularly in food and beverages as a flavor enhancer and preservative. It plays a crucial role in the production of phosphate-based fertilizers like DAP and MAP, essential for plant growth. Additionally, it is utilized in metal surface treatment and the synthesis of pharmaceuticals and detergents.

While generally safe when handled properly, concentrated phosphoric acid can cause burns and eye damage; thus, protective equipment is necessary during handling. Its applications extend across agriculture, food processing, cosmetics, and industrial processes.

-

Phosphoric acid is a versatile compound utilized across various industries due to its ability to adjust pH levels. In the food and beverage sector, it serves as an acidulant and flavor enhancer, commonly found in carbonated drinks and processed foods. Its role in agriculture is significant, as it is a key ingredient in phosphate-based fertilizers that promote plant growth by replenishing soil phosphorus. Additionally, phosphoric acid aids in water treatment by controlling alkalinity and preventing scale formation in cooling towers and boilers. It also finds applications in chemical manufacturing, where it acts as a reactant or catalyst for producing phosphate salts used in detergents and pharmaceuticals. The cleaning properties of phosphoric acid make it effective for rust removal and metal surface preparation. Overall, its diverse applications highlight its importance in enhancing product quality and supporting various industrial processes.

-

West Asia, particularly Saudi Arabia, Jordan, and Morocco, is a significant player in the phosphoric acid market due to its abundant phosphate rock reserves. These countries are major producers and exporters of phosphate-based fertilizers, which utilize phosphoric acid as a key ingredient. The region"s strategic location and access to resources have fostered growth in the phosphoric acid sector. Beyond fertilizers, phosphoric acid is utilized in various industries such as chemicals, food and beverages, and metal treatment. The increasing industrialization in West Asia has heightened demand for this versatile compound. Despite being a major exporter, the Middle East also imports phosphoric acid to meet local needs due to lower production levels. Investments in new production facilities are underway but will not be operational until after 2025. For instance, the National Iranian Copper Industrial Company plans to invest 250 million euros into developing phosphoric acid plants that will require substantial phosphate soil imports annually.

The market is expected to grow driven by population increases and rising food demands while facing challenges from price fluctuations and environmental regulations. Overall, the region"s investments in infrastructure and production capabilities position it competitively within the global phosphoric acid market.

-

Phosphoric acid production primarily utilizes the wet process, where phosphate rock is mined, ground, and reacted with sulfuric acid to yield phosphoric acid and calcium sulfate. This method is favored for its lower energy requirements and higher purity of the final product. The wet process involves filtering the mixture to separate solid calcium sulfate from liquid phosphoric acid, which is then concentrated through evaporation. An alternative method, the thermal process, involves burning elemental phosphorus to produce phosphorus pentoxide, which is then dissolved in water to form phosphoric acid. While both methods have their pros and cons, the wet process remains dominant due to its efficiency. Environmental sustainability is becoming a key focus in production practices, with efforts aimed at reducing waste and minimizing ecological impacts. Historical context reveals that phosphoric acid has been recognized for its agricultural benefits since the 19th century, leading to its widespread use as a fertilizer. As industries evolve, sourcing reliable phosphate mineral ores has become essential due to past challenges with bone prices.

-

Phosphoric acid, derived from phosphorus, has a rich history dating back to the late 17th century when Hennig Brand first isolated phosphorus. The understanding of phosphoric acid evolved significantly in the early 19th century through the work of chemists like Jöns Jacob Berzelius. Initially produced via the bone-ash process, which treated bones with sulfuric acid, commercial production began in the mid-19th century. The wet process emerged in the early 20th century, replacing the bone-ash method due to its efficiency. The molecular structure of phosphoric acid (H₃PO₄) was elucidated in the late 19th century, leading to its widespread use in agriculture as a fertilizer and in various industries such as detergents and food production. Phosphoric acid became essential for enhancing crop yields and was later recognized for its role as an acidulant in beverages. Regulatory bodies have since established safety standards for its use in food products. However, environmental concerns regarding phosphate mining and processing have prompted efforts to improve sustainability within the industry.